A Smarter, Greener Approach to Heating and Hot Water

When a prominent retirement village in Wellington experienced repeated failures in its heating system, they turned to Flow Plumbing & Heating and Waterware to design a sustainable, reliable solution that would improve comfort, lower running costs, and significantly reduce emissions.

The Challenge

The original plant included two aging 80kW natural draft gas boilers—one completely failed and the other nearing end-of-life. The system ran constantly, wasting energy and money. The village wanted to go green but didn’t have the electrical capacity for a fully electric solution.

The Hybrid Solution

To avoid costly infrastructure upgrades, Flow Plumbing & Heating and Waterware designed a hybrid system using:

- Heating Circuit:

3 × 16kW Vaillant Arotherm Plus heat pumps

1 × 60kW Vaillant Ecotec Plus condensing gas boiler

Vaillant weather-compensating thermostats - Hot Water Circuit:

2 × 16kW Vaillant Arotherm Plus heat pumps

1 × 37kW Vaillant Ecotec Plus condensing gas boiler

This setup lets the heat pumps handle most of the load, with gas used only during peak demand or extreme cold.

Performance Results: Big Savings, Low Emissions

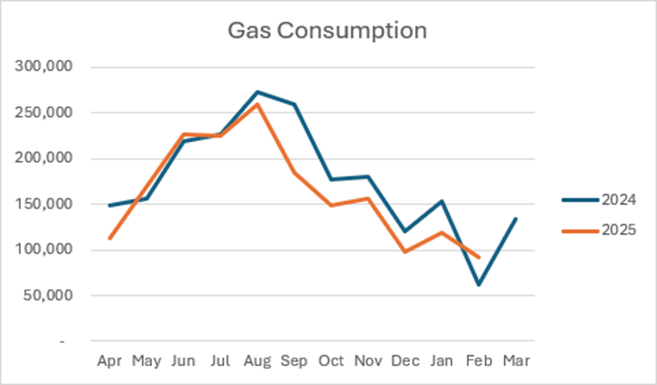

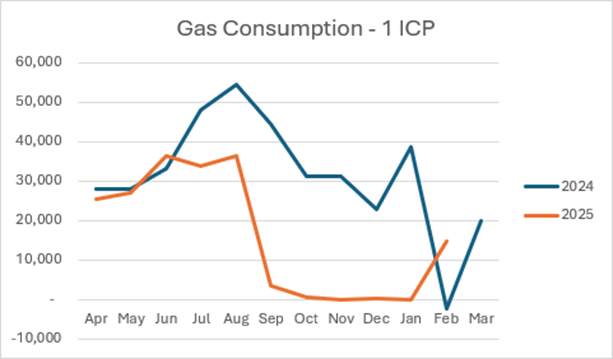

Gas consumption significantly dropped after installing the hybrid system:

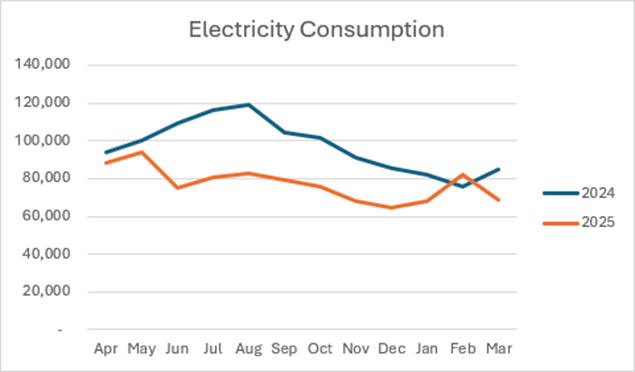

The data confirms that heating demand shifted to electric while keeping overall electricity use steady highlighting the system’s efficiency.

Key Benefits for the Client

– Forecasted $30,000 annual savings in gas and maintenance

– Dramatic emissions reduction by moving away from constant gas usage

– No disruption to residents during installation (thanks to temporary boilers)

– Quiet, efficient performance surprised even the most skeptical stakeholders

– Full support from Waterware, from design to commissioning

“We expected more disruption and noise, what we got was fast, quiet, and smooth. The system just works.”

Let’s Build Your Success Story

If you’re a facility manager, developer, or consultant looking to upgrade ageing heating systems with a smarter, hybrid approach, please reach out. We’ll help you save money, reduce emissions, and future-proof your infrastructure.