Challenges & Requirements

One of the critical challenges of this project was noise management. The facility prioritizes resident comfort and was highly mindful of potential noise disturbances when selecting an installation location for new equipment. Additionally, ensuring reliable and efficient heating performance was essential for a seamless transition away from gas.

The Waterware Solution

To meet these needs, Waterware provided a highly efficient system comprising three R290 Ritter Thermal+ 18kW heat pumps connected in cascade with a small buffer tank in the pool heating plant room. This solution offered:

• High Efficiency: The R290 heat pumps achieve a Coefficient of Performance (COP) of 4.4, significantly outperforming traditional gas boilers.

• Quiet Operation: The cascade configuration ensured a low-noise setup, maintaining resident comfort.

• Reliability: The system was designed to provide consistent and effective heating, fully replacing the previous gas boiler.

Performance & Cost Savings

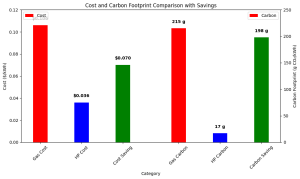

Running Cost Comparison:

• Gas System: With a gas cost of $0.09 per kWh and a boiler efficiency of 85%, the effective heating cost per useful kWh was $0.106.

• Heat Pump System: With an electricity cost of $0.16 per kWh and a COP of 4.4, the effective heating cost per useful kWh was $0.036.

• Cost Savings: The switch to heat pumps resulted in an approximate 66% reduction in heating costs.

Carbon Savings: Transitioning from gas to heat pump technology significantly reduced the facility’s carbon footprint. Heat pumps operate with far lower emissions compared to gas combustion, contributing to a cleaner, more sustainable energy future.

• Gas System: With a carbon foot print of 183 g CO₂/kWh and a boiler efficiency of 85%, the effective carbon foot print of 215 g CO₂/kWh

• Heat pump System: With a carbon foot print of 77 g CO₂/kWh and a COP of 4.4:1, the effective carbon foot print of 17 g CO₂/kWh

• Cost Savings: The switch to heat pumps resulted in an approximate 90% reduction in carbon foot print.

Market Differentiation

Waterware’s use of R290 refrigerant technology sets it apart from conventional heating solutions. This innovative approach ensures:

• Superior efficiency and lower operational costs

• Environmentally friendly performance with reduced greenhouse gas emissions

• Long-term sustainability with reliable, high-performance heating

Future Opportunities

Waterware has extensive experience in converting heating systems across various applications, including domestic hot water, pool heating, air handling, and space heating. The successful implementation at this aged care facility in Karaka demonstrates how Waterware can support similar projects in achieving energy efficiency and sustainability goals.

Conclusion

By replacing a gas-fired system with an advanced heat pump solution, this aged care facility in Karaka achieved substantial cost savings and carbon reduction while maintaining a quiet and reliable heating system. Waterware continues to lead the way in sustainable heating solutions, helping facilities transition to greener alternatives without compromising performance.